Understanding the Electroforming Process

When I discovered the electroforming process it was like a creative lightning strike. My jewelry has always been organic and rather unique. When I saw a few electroformed pieces I was intrigued and immediately excited. I immediately knew that this would be something I would love, and could make "my own."

Looking at electroforming it reminds me of alchemy. With this process I can turn things into metal or deposit metal where none existed. The process is mad scientist meets jewelry artist. The process is not entirely predictable so if you were a scientist and were trying to electroform you would be disappointed. If you were just a pure artist the process is complicated and not immedatatly gratifing. Electroforming especially in silver (not nickel) is difficult. On all of etsy with 6 million pieces of jewelry for sale, only around 1,000 are made with this process. That even includes "dipping" which is a poor brother of electroforming. So science and art together is electroforming.

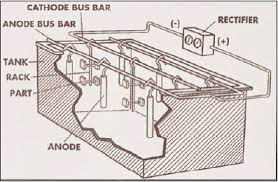

The definition of electroforming is the intricate process of controlling chemically a metal deposit (copper, silver, gold) onto a conductive surface whether it be an organic or inorganic material. This process is similar to plating...but is done over a much longer period of time - and can be anywhere from 1 - 18 hours. Basically a thick “skin” of metal is built up into a rigid surface. I used this technique to make bezels, rings, pendants, large constructed necklaces, and to enhance or improve some of my forged or crocheted wire components.

My electroforming process varies from one piece to another. However, it generally includes a thick copper build up, a thin nickel layer and finally a thick 24k gold or fine silver layer. Sometimes, I only use copper in the process. I incorporate Swarovski crystal, natural gemstones, or other common objects like acorns, roman twigs, coins, etc in the process. Occasionally, some of my wire crochet elements also find their way there. The object being electroformed can be a permanent part of the end product or can be temporary (as in the case of wax), and removed later, leaving only the metal form, the "electroform".

Electroforming is a rather specialized process of fabricating metal parts and has involved a rather large investment in capital, time, and research on my part. I have really enjoyed the process and quickly it has become one of my favorite techniques. I will always crochet wire, metalsmith, and electroform. No matter where the art of it all leads me.